Partner Resource to provide printing options of an size or scope

To see a complete list Download our Capabilities [PDF]

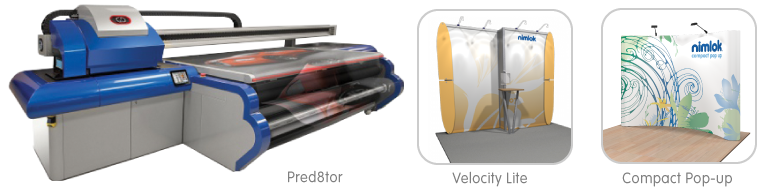

UV Printing

With three state-of-the-art UV printers, we provide vibrant graphics with excellent longevity on a variety of rigid and flexible substrates such as multiple extruded, wood and textured surfaces. This print process uses ultra violet light to cure the ink onto the substrates. Once cured, the ink is bonded to the substrate and will not require lamination. The UV print process is the perfect solution for our Compact and Velocity product lines, as well as many other custom graphic applications.

Digital Cutter

Utilizing two ZUND digital cutters, we create fast and efficient workflows for finishing graphics. Our equipment has the capability of cutting a wide variety of graphics from basic mural panels to custom contour shaped graphics up to a 2″ thickness.

Solvent Printing

Our three high-speed solvent printers have the capacity to print 1,500sq. ft. per hour. The solvent printing process employs durable and vibrant inks that promote strong adhesion and excellent longevity. With a robust resistance to fading and scratching, solvent printing is ideal for both indoor and outdoor applications. Solvent printing is an economical alternative for banner stand graphics.

All solvent printed graphics are finished on a state-ofthe-art automatic cutter, which trims graphics up to 50 ft. per minute. The combination of our high-speed solvent printers with this cutting technology enables us to provide a remarkably fast turnaround time on all FLATMAXX banner graphics.

Dye-Sub

With nine cutting-edge fabric printers, we have the ability to print a remarkable 3,400sq. ft. per hour. This high-speed process produces vibrant, six-color output up to three meters wide. All dye-sublimated fabric graphics are finished to maintain shape and quality. Our highly-skilled sewing staff finishes each graphic by hand to ensure the perfect fit to the exhibit or display frame. Dye-sublimated fabrics are used for a number of Nimlok product lines including Wave, Velocity, Pulse and SmartWall. Custom graphic finishing such as zippers, silicone beading, hemmed edges and pole pockets are available upon request.

G7 Certification

In the fall of 2010, Nimlok achieved G7 Master Print specification.

G7 certification helps ensure the production of the highest quality, consistent and accurate color graphics. G7 specifies the components of an image that define a similar “visual appearance” to the human eye.

G7 specification:

|

|

Nimlok is among the first companies in the tradeshow industry to attain the specification for G7 digital printing and is proud to be a part of select group of printers throughout the world that can produce consistent, high quality graphics with accurate color to the G7 specification.